Geological hazard monitoring solution with 4g industrial router

The geological disaster monitoring solution based on the Industrial Internet of Things uses the E-Lins industrial 4g sim router H685 and various sensors to realize real-time monitoring and early warning of disasters such as mountain movement and slope deformation.

Geological disasters occur frequently, posing a great threat to people’s life and property safety and economic construction. By using industrial Internet of Things technology to monitor geological disasters, it is possible to achieve early warning and real-time monitoring of geological disasters such as mountain movement and slope deformation, and protect people’s life and property safety. This article proposes a geological disaster monitoring scheme based on industrial Internet of Things, which mainly includes the following contents:

Monitoring scenario: Select areas prone to geological disasters as monitoring objects, such as mine slopes, reservoir dams, debris flow streams, etc. According to the terrain features, rationally arrange the monitoring points to ensure effective monitoring of the threat targets.

Monitoring equipment: Including video surveillance equipment, satellite positioning terminals, stress meters, displacement meters, seepage pressure meters and other sensors. These devices are connected to industrial routers through serial ports or Ethernet interfaces.

Industrial router: Use E-Lins industrial 4g sim router H685, which is designed for industrial Internet of Things applications and has the ability to withstand harsh environments. Equipped with 4G module, it can wirelessly transmit the monitoring data.

Data transmission: The industrial router transmits the monitoring data collected by various sensors, such as video, image, positioning, displacement, stress, etc., to the backend monitoring center in real time for relevant analysis.

Edge computing: The industrial router can realize edge computing locally, preprocess the data, extract key features, and reduce the amount of data transmission.

Data display: The monitoring center uses an industrial touch screen to display the data of each monitoring point in real time, showing the state of the mountain or slope intuitively.

Early warning system: The backend system combines historical data, real-time monitoring data and meteorological models to achieve early warning of geological disasters. Once it exceeds the safety threshold, it triggers an alarm.

Video surveillance: Through the PoE power supply function of the industrial router, it can power the camera. Real-time transmission of surveillance video to understand the mountain situation.

The industrial router supports RS485, RS232, analog input and other interfaces, which can connect more sensors. The router also supports remote management and firmware upgrade, making the maintenance of the monitoring system more convenient.

Industrial routers help to build a highly efficient and real-time geological disaster monitoring scheme, which can not only protect people’s life and property safety, but also provide site safety analysis for other engineering construction. It has a wide range of application value.

E-Lins 4G router H685 is recommended for the geological disaster monitoring project because it has the following advantages:

It has a rugged design that can withstand harsh environments such as high temperature, humidity, dust and vibration.

It supports 4G LTE network that can provide high-speed and stable data transmission in remote areas.

It has multiple interfaces that can connect various sensors and devices for data acquisition and control.

If you are interested in E-Lins 4G router H685, you can visit their website for more information or contact their sales team for a quote.

Networking

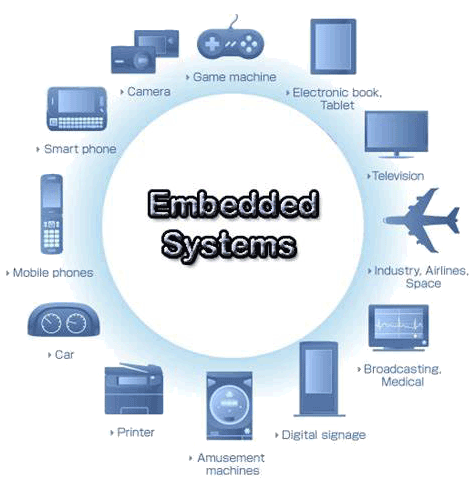

Networking EMBEDDED SYSTEMS

EMBEDDED SYSTEMS Switches

Switches Wireless Solutions

Wireless Solutions Industrial Computer

Industrial Computer Cloud Services

Cloud Services