Remote Water Level Monitoring and Control Solutions

The 4g router with ethernet remotely monitors and controls the water level through the management platform

Where tank level signals are used, they can be wired (dedicated or leased line) or wirelessly (telemetry) from the tank to the pump controller. Wireless telemetry systems are used when the tank and pumping system are located far apart and a wired connection is impractical or unavailable.

Operators of water systems also need to be able to remotely monitor water levels and pumping systems. This is usually performed through an H685 industrial router in large water systems or an alarm call system in smaller rural water systems.

H685 industrial 4g router with ethernet provides a flexible solution for water level monitoring and control

The H685 Industrial Router system is designed to provide remote I/O replication of analog or digital signals. Using the H685 industrial router or industrial dtu I/O signal duplication allows for easy connection to hardwired or PLC based pump control systems. For water systems, I/O telemetry is used to interface the tank level signal to the pump control system. This I/O telemetry allows for independent level control independent of the communication network.

Customers can easily connect the telemetry network via RS232 or RS485 Modbus on the H685 industrial router interface, allowing connection to any node via Modbus protocol.

A wireless network based on the H685 industrial router can be used with a dual-mode satellite/cellular IoT hub to provide cloud-based access to the pump train. The system can be used in point-to-point mode for I/O replication. I/O replication can be analog (4-20ma level transmitter) or digital (high level flow, low level switch). While typical signal transmission requirements are one-way transmission from the tank to the pumping station allow two-way signal communication. The system can operate in point-to-point or point-to-multipoint mode. When multiple pump stations are used to supply elevated tanks, the tank level signal can be transmitted to multiple pump stations.

Remote management platform terminals allow global connectivity. The terminal can interface with water level and pump station signals via I/O signals, serial RS232/RS485 or Ethernet.

Remote management platform terminal can be connected to I/O telemetry network through RS232 or RS485 of H685, allowing to monitor any signal, PLC, RTU connected to RIO900 network.

The platform offers easy-to-use features, including trend analysis. Using trend functions can help water utility operators detect leaks (A) and estimate water consumption (B). The platform provides time-stamped data (C) that can be used to identify issues.

The H685 and remote management platform provide flexibility for large and small water system monitoring and control deployments. The H685 and the remote management platform can be deployed together, separately or in stages. The system can be easily expanded from point-to-point to multi-point systems. The flexibility of the H685 and remote management platform allows for purpose-built system deployment.

Networking

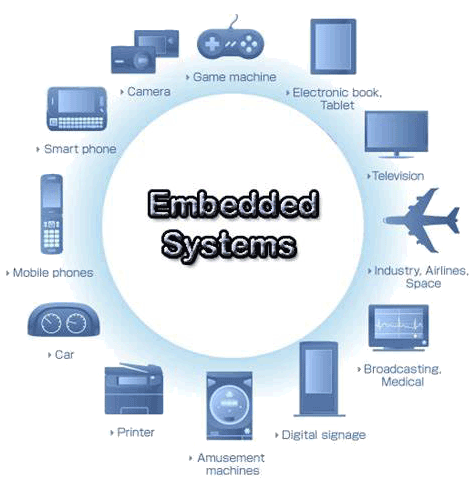

Networking EMBEDDED SYSTEMS

EMBEDDED SYSTEMS Switches

Switches Wireless Solutions

Wireless Solutions Industrial Computer

Industrial Computer Cloud Services

Cloud Services